So here you are with your new empennage projects and perhaps limited skills. The plans direct you to trim a piece of aluminum along a line drawn between two notches. Seems easy enough. Mark the line and then trim off the excess with a band saw. Except the band saw blade develops a mind of its own and channels beyond the cut line and now you have an ugly cut and have perhaps turned a piece of aluminum to scrap.

This happened to me on my first build and I ended up getting new parts as the ones I cut looked very, very ugly. The solution is quite straightforward if you have a bench sander.

Mark Cut Line

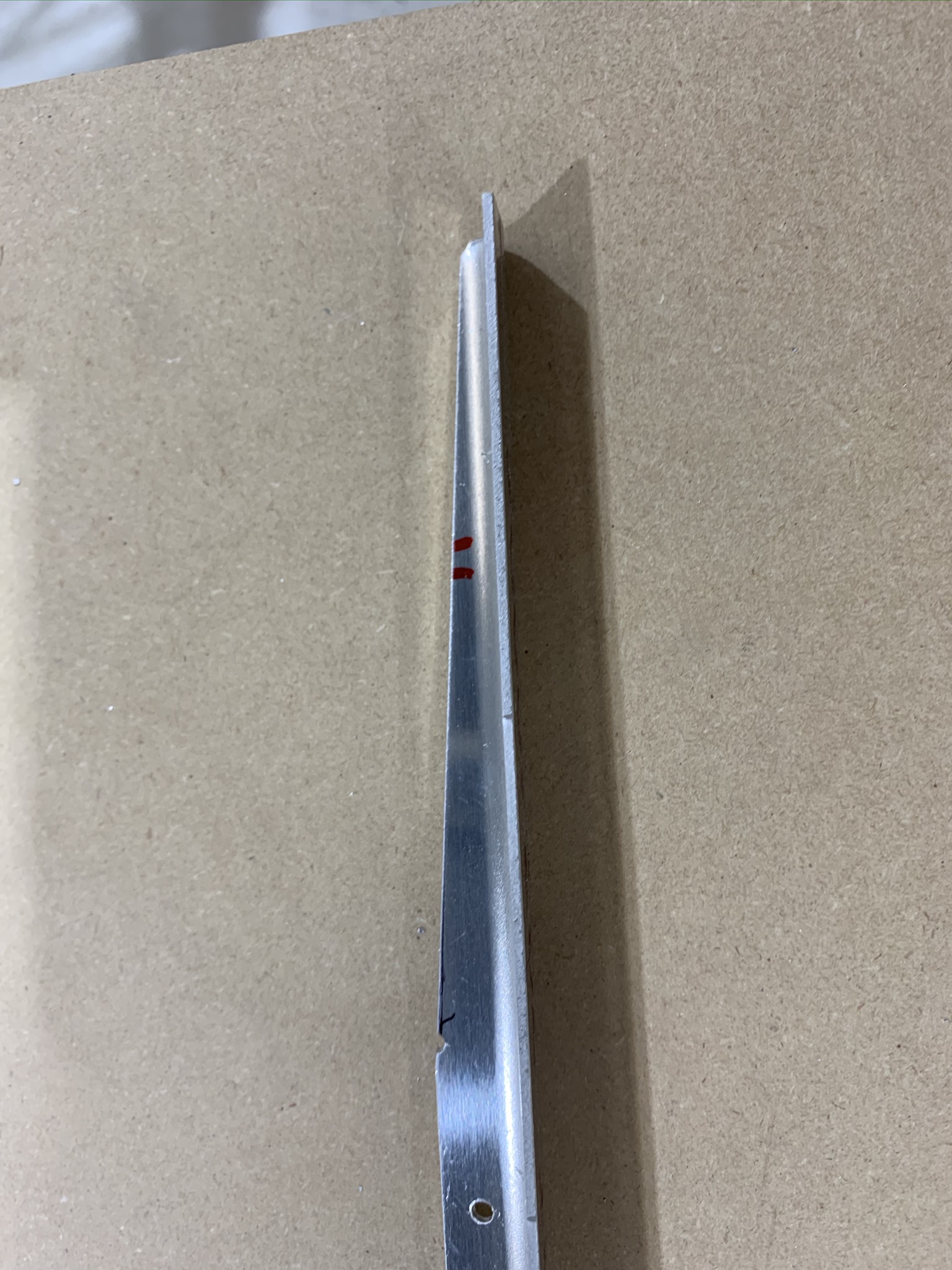

Cut proud of line

Sand down to line on belt sander

There are many places in the plans where you are asked to make fairly precise cuts. It is my practice to make the cut line, cut proud of the line and then sand down to spec. I find it too easy to make a bad cut with my el cheapo band saw. This way I avoid (usually) a parts disaster.

Another helpful hint is to make sure your band saw blade is sharp. A sharp blade will cut most aluminum we use like butter. A dull blade will struggle. Also, if you use your band saw to cut steel and/or fiberglass, be prepared to replace the blade. Either of these materials will kill a blade quite quickly.