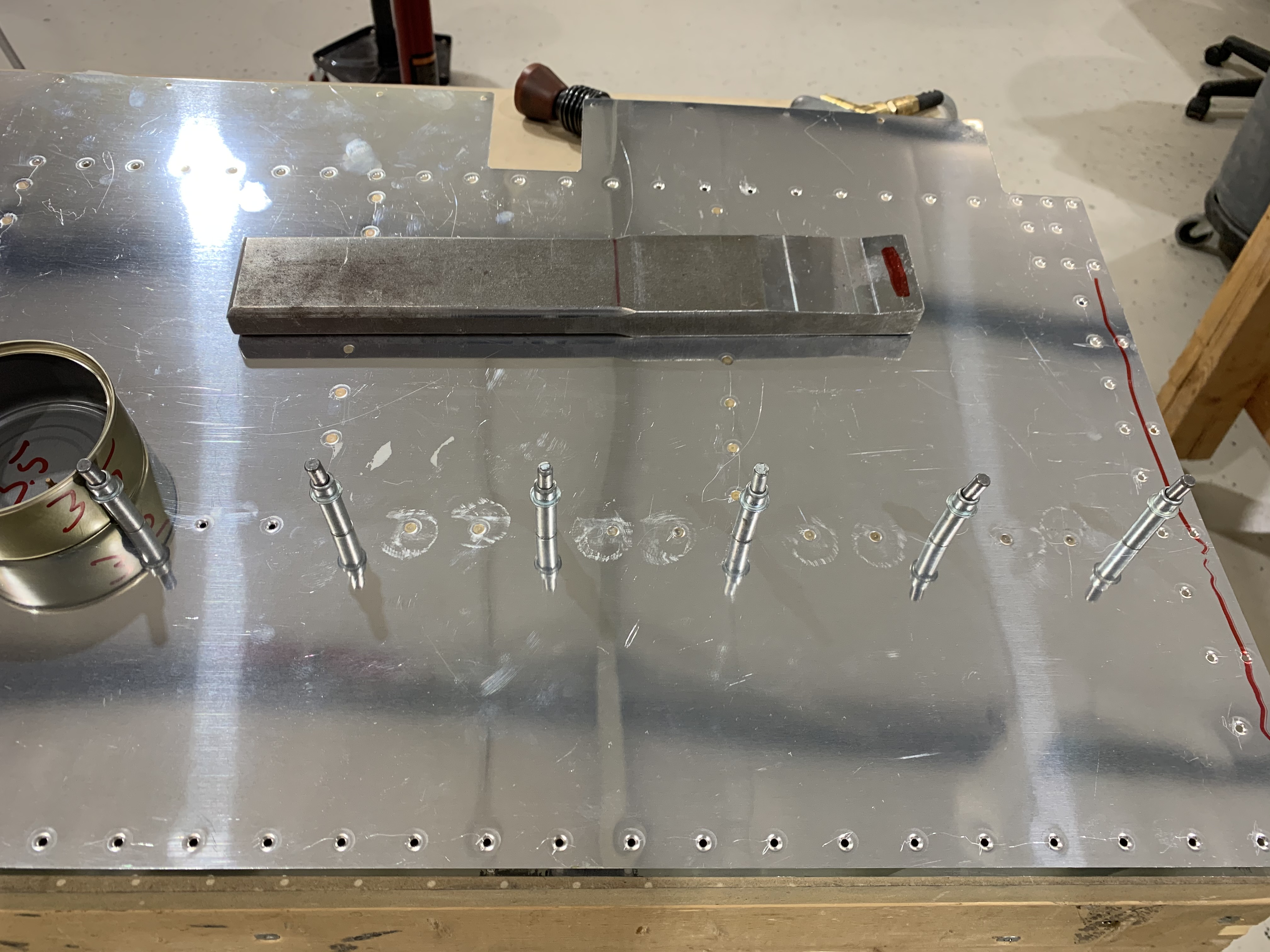

Bucking Bars

Here are the three bucking bars you will need. The tungsten bucking bar will be used 99.9% of the time. Its density (weight) is what makes it so effective when riveting. There are different shapes for the tungsten bar but I found the rectangular on quite functional. The steel bucking bar has a “foot” for getting into difficult spots. The long steel bucking bar is used for the elevators. Get or borrow one. Do not try to do without. Note that I put a red box on the bar as well as a red line on the end. When The red line matches the elevator trailing edge and you can see the red box through the rivet hole, you will know you are aligned correctly for riveting.

There are a ton of other bucking bar shapes you can get. And they will sit in your tool box never used.

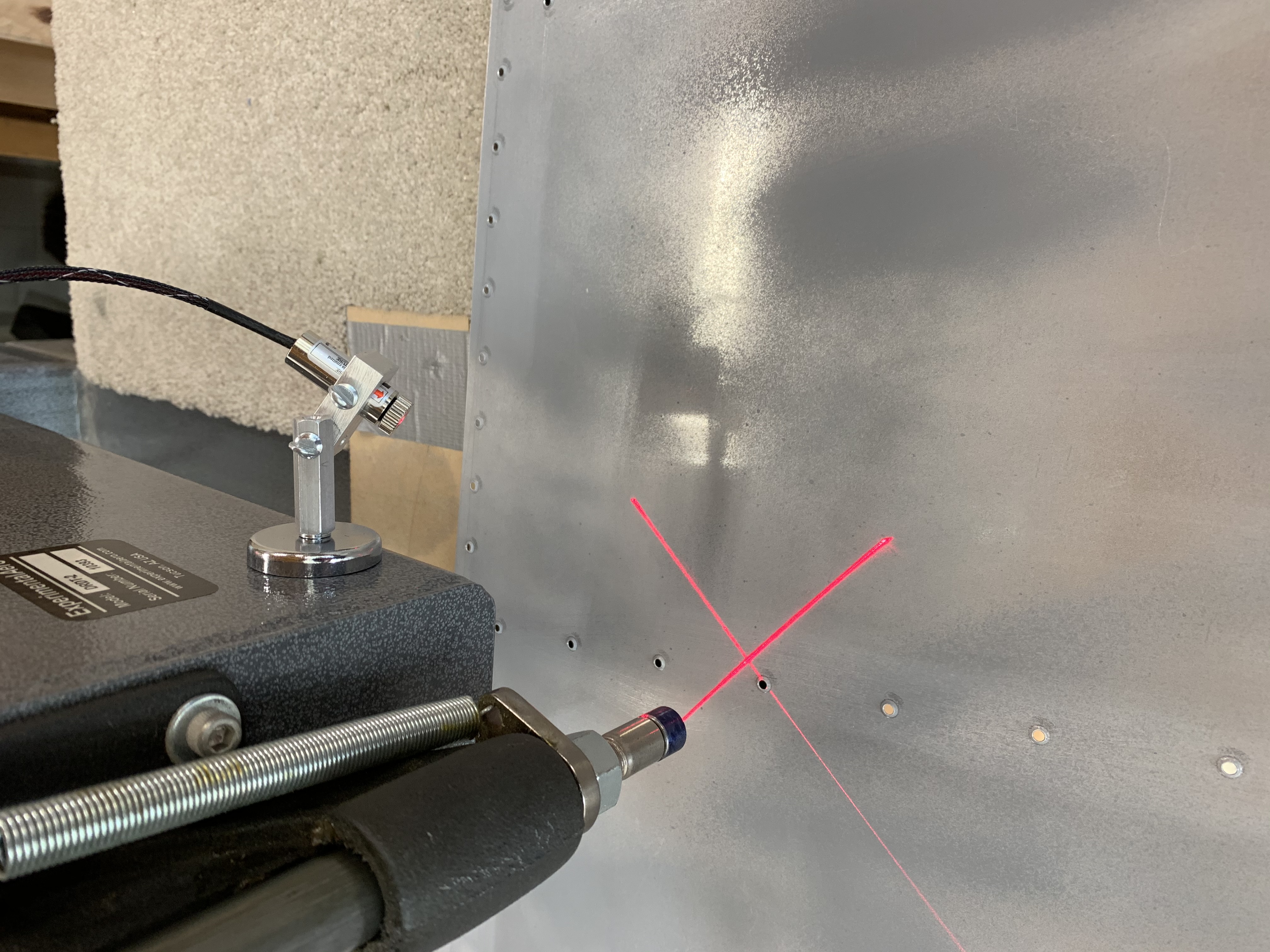

DTDT2 Dimpler Spotting Laser

CleavelandTool sells a cross hair laser that you can use to spot the holes when dimpling. It makes finding the male set quick and easy. There are others that work equally well but this is the one I use.

Trailing Edge Wedge Countersink

Trailing edge wedges need to be countersunk perpendicular to the wedge surface. However the wedge shape makes this difficult to accomplish. CleavelandTool.Com sells a wedge holder that makes this operation fast and simple.

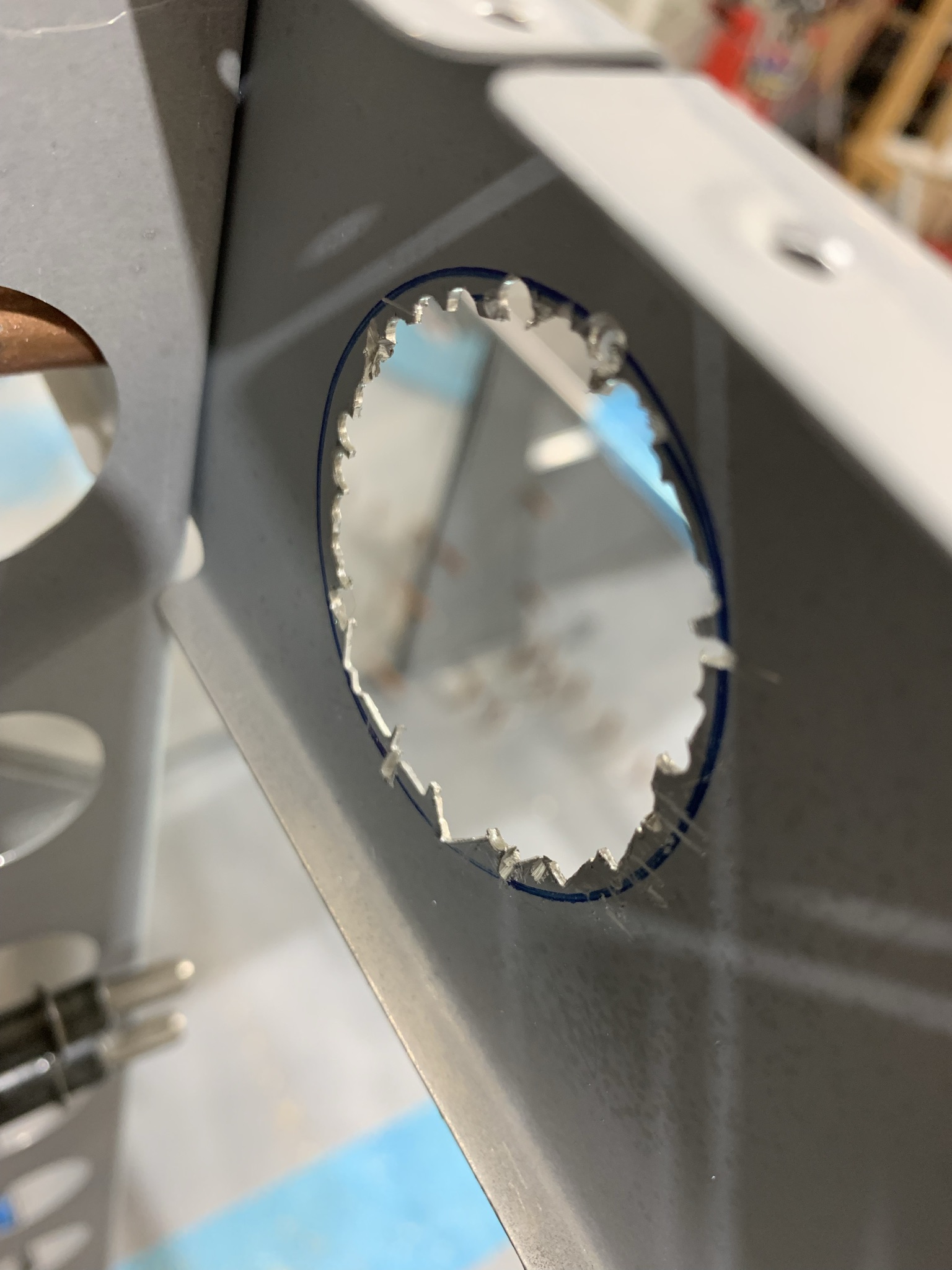

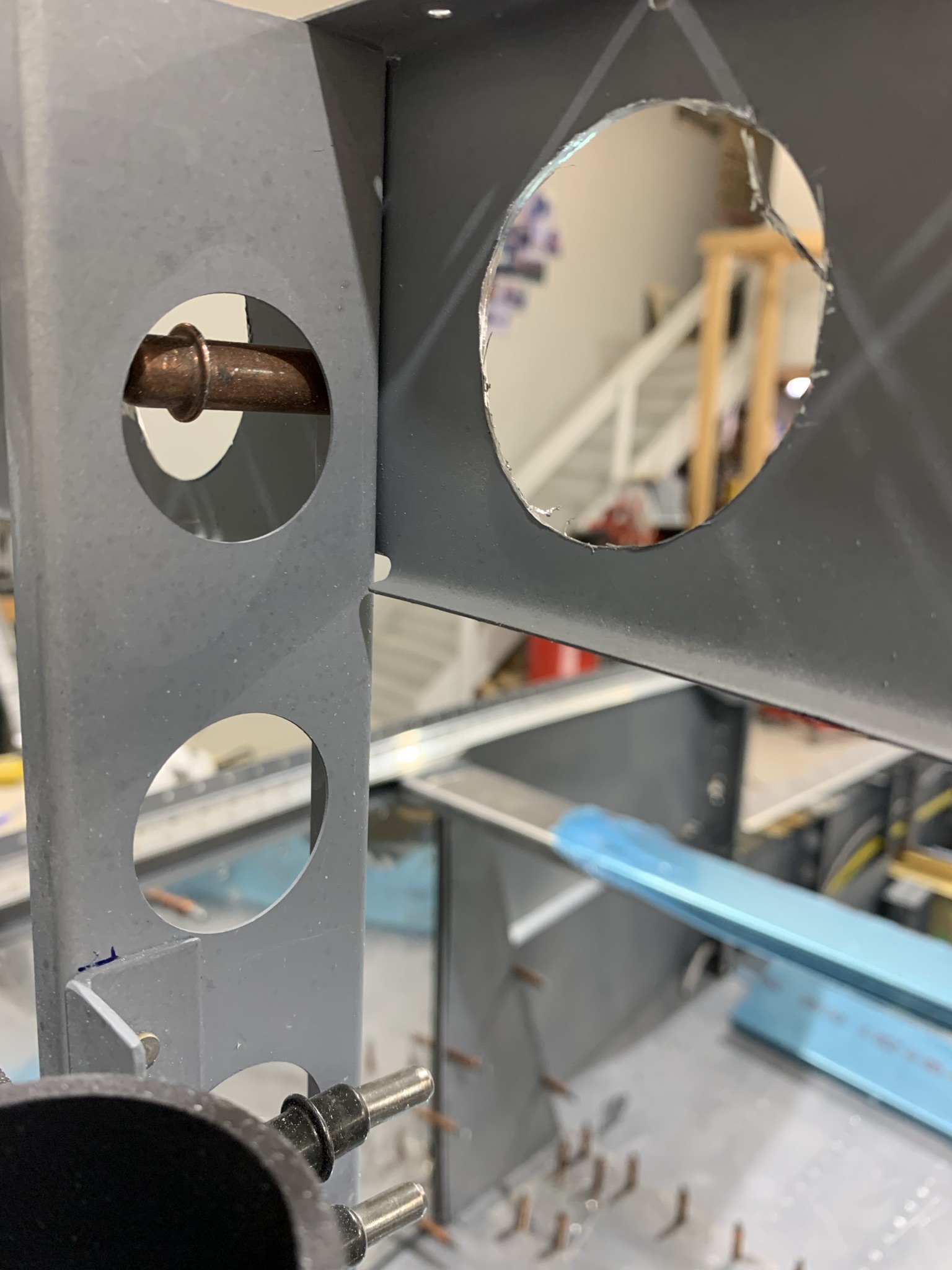

Carbide Cutter

I recently had to cut two 2″ holes in a tail cone bulkhead to accommodate air flanges feeding air into the overhead console in the cabin. To roughly cut the holes, I drilled a perimeter of holes and then cut the centers out. Normally I would have used files etc to clean up the hole. In this case I used a carbide cutter attached to a die grinder to remove all the extraneous material. It took all of 30 seconds to clean up the hold. I then used a deburring tool to remove the burrs.

A Third Hand Tools

Aircraft Spruce sells a “Handee Clamp” which allows you to hold fasteners where your fingers can’t reach or go. The one in the pix is holding a nut that was being placed on a rudder rod end bolt.

Below it is a set of washer holders from CleavelandTool.Com. In many locations your have to insert washers between brackets and rod ends etc. These holders make it possible to easily insert washers in these tight spaces.

.

.

.

.

.

.

.

Finding Leaks & Tight Nutplates

These two products have nothing to do with each other than I put them in the same pix. SNOOP is a leak finding liquid. It works the same way as soapy water would in finding air leaks except it is 1,000% better. It will form bubbles where there is the slightest of leaks. I used it on my tire valve to detect a very slight valve leak that was causing my tires to lose about 10 PSI over a month. I originally received this from Mountain High Oxygen as an aid to trouble shoot leaks when installing my O2 system.

Beolube was developed by Boeing ( of 7×7 fame) as a lubricant. I use it as a cutting oil when drilling steel. It is also very useful when inserting screws into tight nutplates – especially small nutplates where the risk of shearing a screw off is great. It is cheap and very, very effective.

Crimping Tools

When building, you will be presented with a number of different wire connectors that you will need to install. Typically each requires a different crimping tool. You can minimize the number of crimpers you need if you purchase a crimper tool (frame) that takes different sets of jaws. Each set of jaws specific to a particular type of connector.

I found the Greenlee / Paladin crimper to be very useful . Here it is on Amazon.