Sometimes you run into a rivet that you can’t figure out how to set. In my case it was a rivet I missed setting on the upper engine mount weldment that needed to be set BEFORE the side skin was installed. In my case I was hooped as there was not enough room to use either a pneumatic or hand squeezer. I tried (several times) to use a Cherry Max pulled rivet but it would not set correctly as the hand riveter was not pulling in the shank squarely.

Hole that needs a rivet

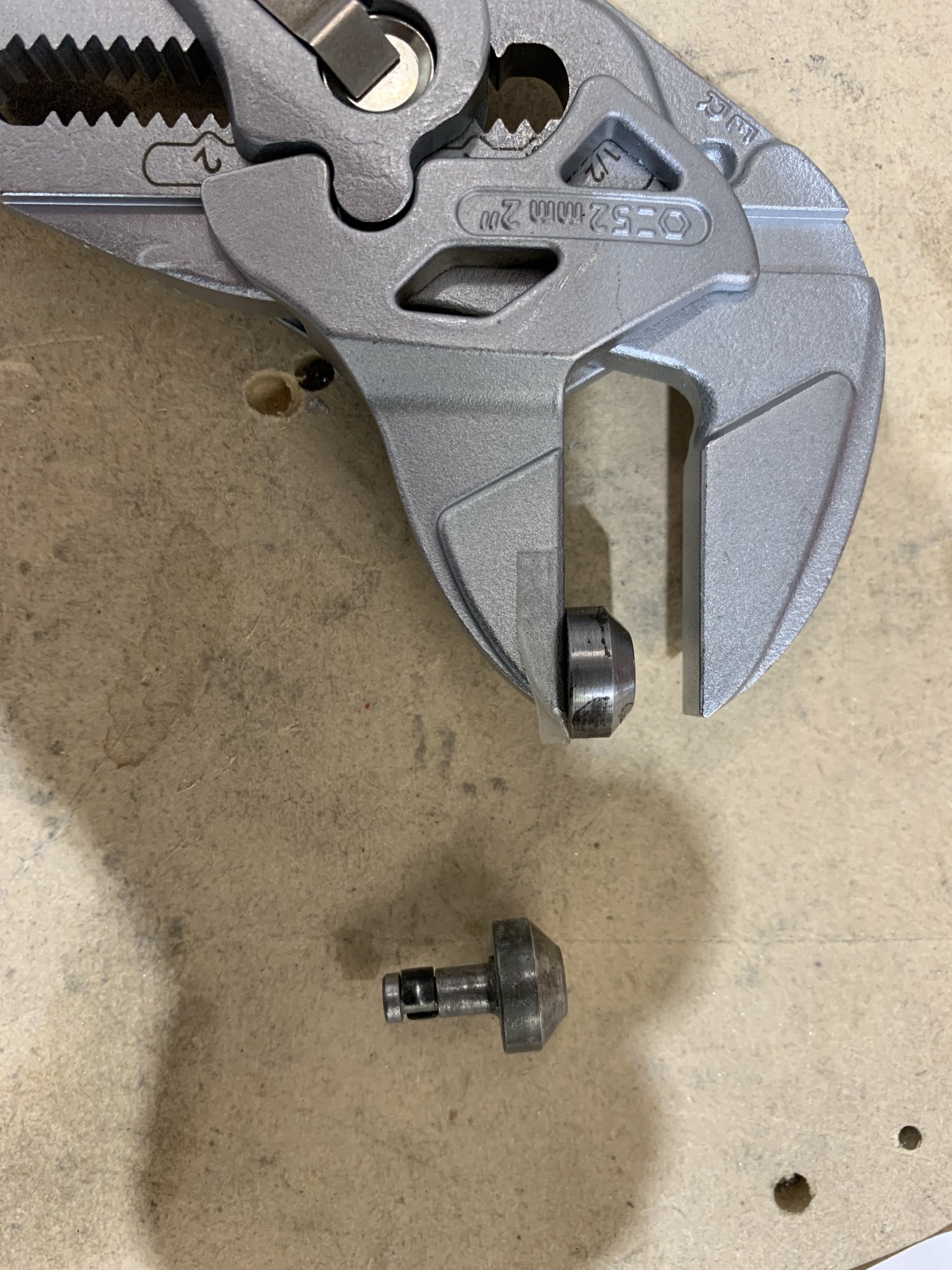

Knipex pliers with rivet snap

squeezing rivet

Final result – perfect

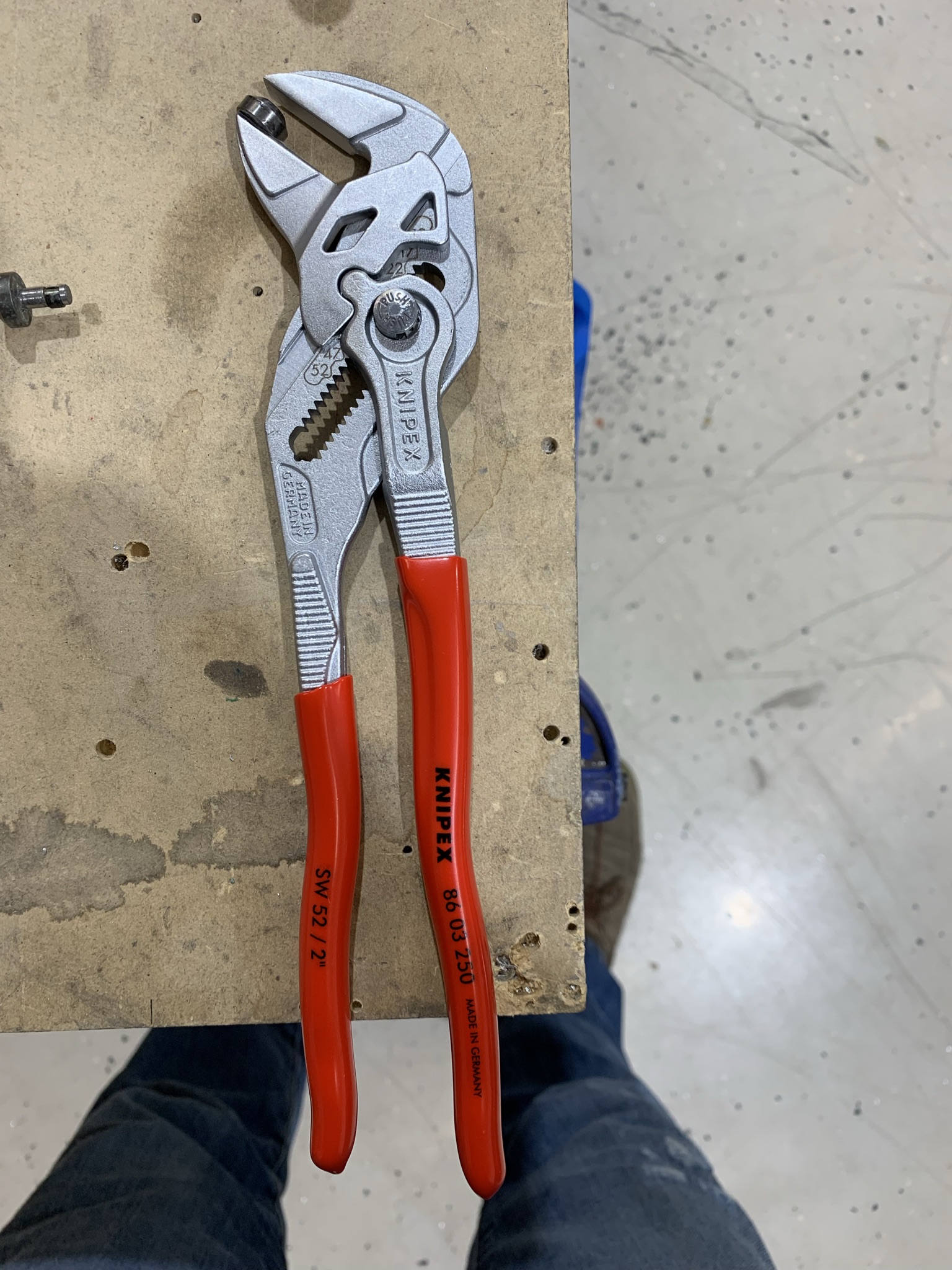

Knipex pliers – full view

Ultimately I was able to find a solution that worked although it was not obvious. I took an AN470 rivet set and cut the base off. I then used two sided tape to hold it on a set of Knipex pliers. I then used the pliers to squeeze the rivet. It was a bit tough but the job got done.

The Knipex pliers are unique in that the jaws open and close parallel to each other. This is important as the set needed to move squarely to the rivet. If regular pliers were used, the rivet set would have been on an angle and the rivet likely would have had a cut edge – not good on a engine mount weldment.

Other Problematic Rivets

As someone much wiser than me once said, “A Cherry Max rivet is always an acceptable replacement for solid rivet in a blind condition”. In other words, if you need to put in a solid rivet and can’t consider using a Cherry Max rivet. There are some rivets that are difficult to set. If You find that you are drilling a rivet out, consider using a Cherry Max if you think there is a risk that the same problem, will reoccur.

Cheery Max rivets come in various lengths so be sure to use the correct length. See Paul Dye’s video below.

Here is a link to a video on pulled and Cherry Max rivets by Paul Dye of KitPlanes mag

Here is a link to a Van’s video on lubricating Cherry Max Rivets prior to use.

When all else fails, it is also acceptable to use a nut / bolt to replace a solid rivet provided it can be installed with appropriate edge distance.