System checkout is straightforward. The guide below details the process I used and highlights a few common oversights that can lead to problems. The SDS EM-6 manual contains an extensive troubleshooting guide that can resolve many more common installation problems.

Before running the engine it is imperative that you confirm the installation is correct in all respects. The above assumes that you have installed all SDS and related hardware according to manufacturers instructions. Be sure to double check the hardware installation is correct in all respects. See the SDS installation manual for detailed instructions.

SDS Configuration Data

As a first step, power up the SDS system. Download and print the SDS configuration data (ECU Map). Instructions on how to do this can be found here.

Withe the exception of the magnet position values, all values in the ECU maps should be the same for the primary and secondary ECU. Cylinder trim values should be set to 0%. LOP Lean Fuel % should be 0. LOP Ign Adv should be 0.

The EM-6 Manual contains a section titled System Operation and Programming Section. Read this section carefully and make sure you understand the concepts presented.

EFIS Configuration

The EFIS configuration does not affect the operation of the SDS system. However, if the EFIS is not configured correctly, key engine information will be reported incorrectly on the EFIS. Check and double check the following sensors have been correctly specified in the G3X configuration page.

- Outside Air Temperature Sensor

- Manifold Pressure Sensor

- Fuel Pressure Sensor

- Oil Temperature Sensor

- Oil Pressure Sensor

- Fuel Flow Sensor

- CHT Probes

- EGT Probes

The fuel flow sensor should be set to the EI FT60 option and the “K” factor set to 28,500. The ECUs provide a fuel flow signal to the EFIS and this configuration will tell allow the EFIS to interpret the signal correctly. The “K factor is close to what is required in an IO-540 and accurate enough for initial flights. Your EFIS documentation will specify how “tweak” the “K” factor for greater accuracy.

With the SDS system powered up (including the electric fuel pumps), confirm the following on your EFIS:

- Fuel pressure is 45-50 PSI

- RPM is 0

- Manifold pressure matches ambient temperature

- Bus voltage is nominal

- Outside air temperature matches ambient temperature

- CHT temperatures match ambient temperature

- EGT temperatures match ambient temperature

- Oil temperature matches ambient temperature

Confirm the following on the SDS display checking both ECUs.

- Gauge 1 : MP (Manifold pressure) matches ambient pressure

- Gauge 1 : ET (Engine temperature) matches ambient temperature

- Gauge 1 : RPM is 0

- Gauge 1 : AT (Air temperature) matches ambient temperature

- Gauge 2 : Knob (Mixture control) moves from about -50% to +50% when rotated.

- Gauge 2 : AP (Acceleration pump) is 0

- Gauge 2 : Duty is 0

- Gauge 2 : IGN (Ignition timing) is -5 degrees or whatever the ignition setting is in the map for 0 RPM.

- Gauge 3 : BAT (Battery) displays battery voltage

- Gauge 3 : TP (Throttle position) changes up and down as throttle is open / closed

- Gauge 4 : BARO (barometric pressure) displays ambient pressure

- Gauge 4 : O2 (oxygen sensor) displays –.–

If ERR is displayed on any of the gauge displays, determine and resolve the source of the error before proceeding.

If any of the above are out of tolerance on the EFIS or the SDS display, check that the correct sensors have been selected in the EFIS and the SDS system. Confirm that there are no wiring wiring issues.

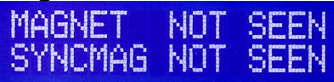

As a final check before starting, confirm that the flywheel magnets are installed correctly by going to the Magnet Seen/Not Seen window on the SDS display.

This window is used to check hall sensor alignment with magnets. To check alignment you must rotate the crankshaft very slowly by hand. Some SDS Hall sensors are adjustable, so sensor alignment with magnets is very critical to system operation.

The LCD window will change to SEEN when a magnet is over the sensor. Check all magnets for being SEEN. Failure to “See” the magnets can lead to a no start condition or misfire at higher RPM’s. Each magnet should be SEEN for at least 2 to 3 degrees of crank rotation. This window is not valid if the engine is running.

As well, the two sync magnets must be SEEN.

If problems cannot be resolved, contact SDS for guidance BEFORE engine start.