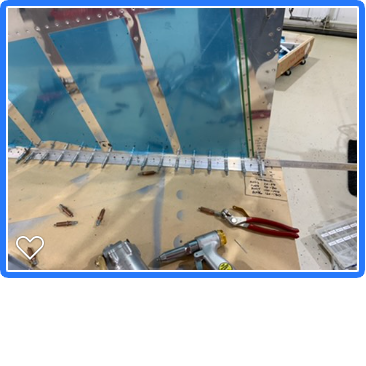

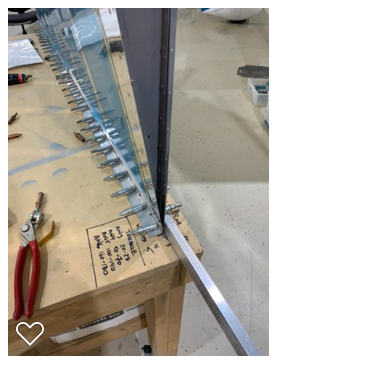

The plans have you place weights on trailing edges that are lying flat on a work bench while the adhesive used to glue the trailing edge wedges in place sets. My solution was to to use 1.5″x1.5″x.125″ aluminum extrusion (angle) from a local metal shop. I used the cheapest available.

I match drilled the trailing edge through lone piece and then match drilled that piece into the other. Lastly I clecoed the angles to the edge. As you can see, the edge stays brutally straight and the skins are tight to the interior wedges.